Expert Consultancy in Polyurethane Processing

At PUPie Limited, we deliver specialized consultancy services for businesses in the offshore oil & gas and power generation sectors. Our expertise ensures that polymer processes are optimized, enhancing quality and minimizing waste. Let us help you achieve excellence in your operations.

Your Partner in Polyurethane Excellence

Bringing a wide range of process experience; from polymer extrusion, injection moulding, FBE powder application by flocking and fluid bed dipping, surface preparation, high and low-pressure wet spraying. Processing of PU foams and elastomers using a wide range of process plant. Composite moulding including carbon, mineral and glass fibre, hollow glass microsphere (HGMS / glass bubbles) and macro-spheres, aggregates and heavily filled PU systems.

20+

Years of Experience

10+

Successful Projects

7+

Industries Served

About the Owner

A data driven decision maker with 40+ years in factory automation, with global experience.

Project Managemt of process modernisation and optimisation. Development of new processes methods with project management of the whole supply chain from specification, design, procurement, installation and commissioning.

Introduced new technologies to the polyurethane industries, working in offshore thermal insulation and cable protection, helping to establish my contacts as leading experts in the field.

Working in diverse industries from precision engineering, powder processing, machine development, pipe-line coating, cable protection, composite moulding and vacuum casting.

Polyurethane Processing Expertise

Trouble Shooting, covering the full process of casting polyurethane elastomer and foams. Having a breadth of experience and techniques used to identify the critical interaction between the chemistry and the process technology, how subtle variations in process conditions can influence product quality.

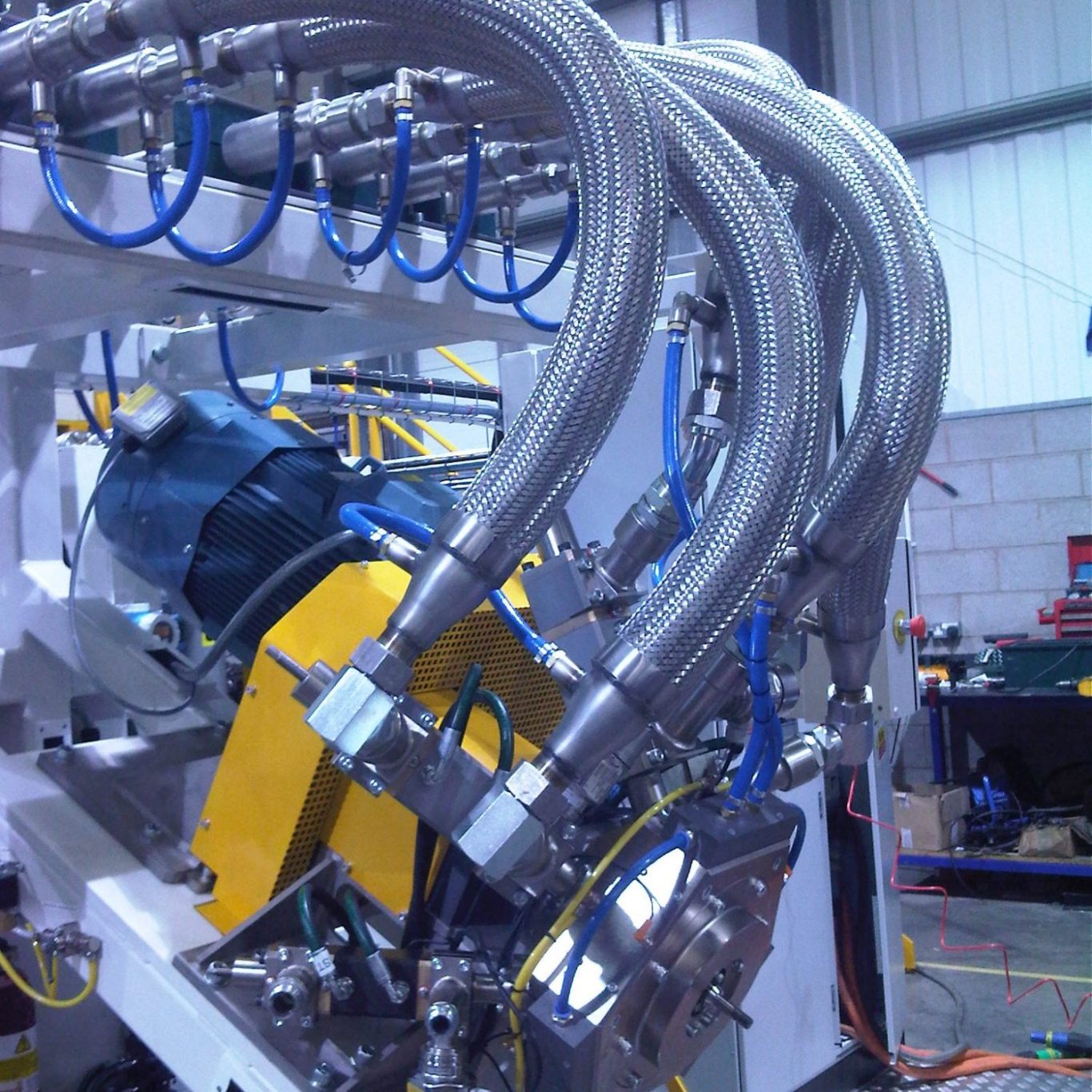

PU Machine Up-grade to remove or mitigate against process issues and unplanned breakdown, improving machine availability and de-skilling. Giving existing assets a new lease of life.

Continuous Improvement Initiatives

We implement tailored continuous improvement strategies that help organizations enhance their operational efficiency and achieve better results.

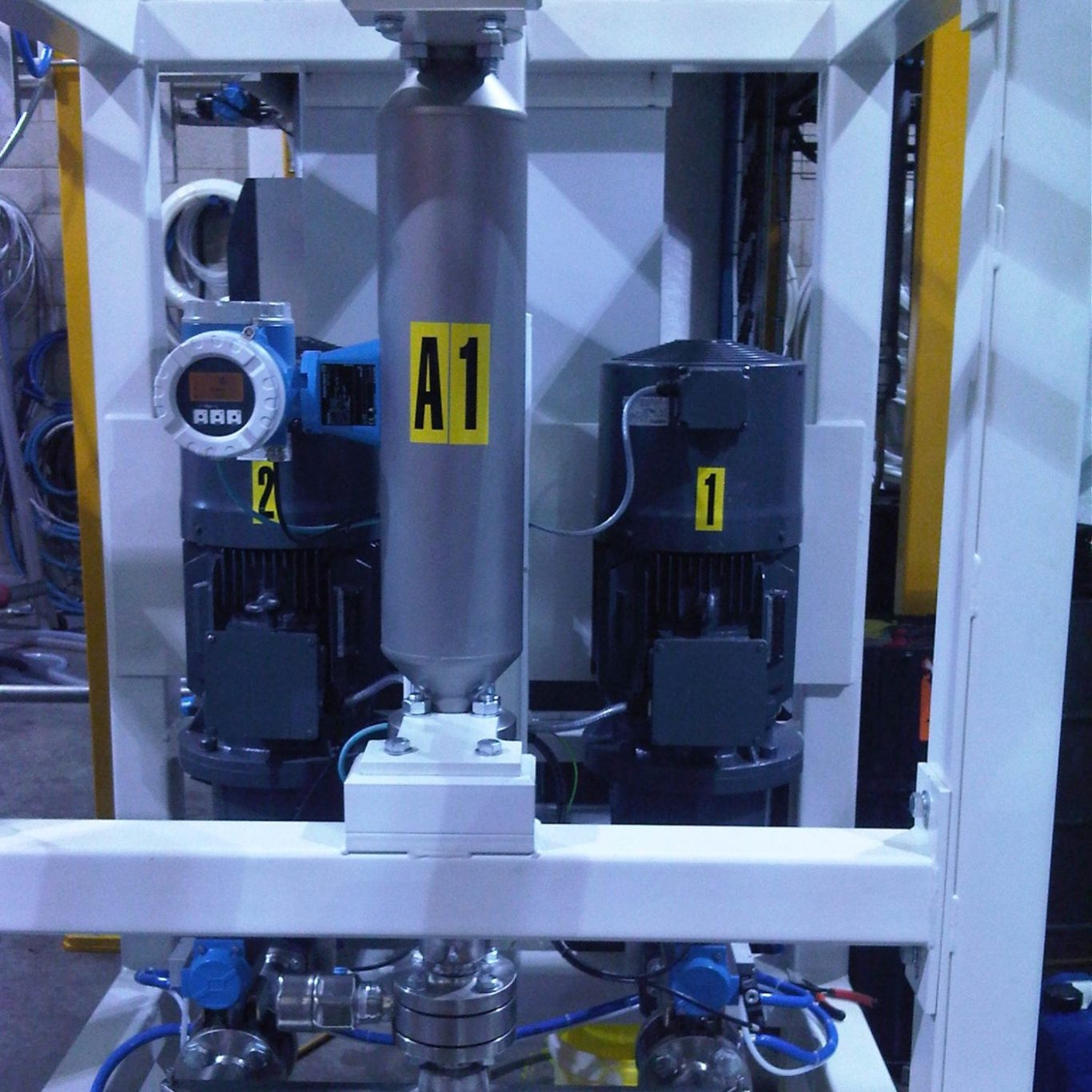

An example is the now widespread use of Mass-flow Meters to PU processing with data acquisition DAQ, in line with Industry 4.0.

Robust Offshore Solutions

Our services cater specifically to the offshore oil & gas industry, ensuring reliable products and processes are in place to meet demanding requirements.

Procurement of mobile polyurethane process plant to detailed Technical Purchasing Specifications (TPS), incorporating the latest communication technology and remote data acquisition.

Setting up a manufacturing plant for thermal insulation of XMT subsea structure and associated products. Involving full development of power supply, plant layout, procurement of process and plant equipment, commissioning and handover

Custom Machine Design

We offer bespoke machine specification and design, ensuring that all equipment meets project-specific needs and enhances productivity.

Specifying and selecting mould tool designs for casting, while ensuring best value for the project requirements.

Specify, development and management of the design of a new generation of Field Joint Coating (FJC) machines for Serimax, covering Spool-base, Offshore, and Land Lines operations. Presenting our success story to Industry experts at International Conferences.

Get in touch

Get in touch

Telephone: 44 7941346851

E-mail: andrewcstribley@gmail.com

Address: 78 Dock View Road, Barry, CF63 3QQ, United Kingdom

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.